The 138th Canton Fair 2025 showcased groundbreaking developments in the field of electric actuators, a rapidly growing segment within the automation industry. According to a recent market report by Research and Markets, the global electric actuator market is projected to reach approximately $45 billion by 2026, driven by the increasing demand for automation across various sectors, including manufacturing, automotive, and aerospace.

The innovative solutions unveiled at the fair highlight the significant advancements in actuator technology, with a focus on enhanced performance, energy efficiency, and smart connectivity. These innovations not only promise to streamline operations and reduce costs but also align with the industry's shift towards sustainable practices. As businesses seek to optimize their processes, the role of electric actuators becomes increasingly critical, positioning them as essential components in the future of industrial automation.

At the recent 138th Canton Fair 2025, innovative electric actuator solutions showcased a transformation in automation technologies across various industries. Electric actuators, renowned for their precision and efficiency, are set to revolutionize operations in manufacturing, aerospace, and automotive sectors. According to a recent market research report by MarketsandMarkets, the global electric actuator market is projected to reach USD 42 billion by 2027, growing at a CAGR of 5.6%. This reflects an increasing demand for automation and the integration of smart technologies in industrial processes.

The advancements in electric actuator technologies are enabling improved operational performance and reliability. For instance, with the integration of IoT (Internet of Things), electric actuators can now communicate status and efficiency data in real-time, allowing for predictive maintenance and optimal performance. This leads to reduced downtime and increased productivity, a critical factor in today’s competitive landscape. Industries are increasingly adopting these innovative solutions, realizing a potential 20% reduction in operational costs as highlighted by a report from Allied Market Research.

Tip: When considering electric actuator solutions for your operations, evaluate the scalability and compatibility with existing systems. Adopting modular designs not only fosters flexibility but also accommodates future technological enhancements without significant overhauls. Keeping an eye on the latest trends in electric actuators can lead to smarter, more efficient automation strategies that align with current industry demands.

The electric actuator market is poised for remarkable growth, projected to reach

$XX billion by 2030. This surge is driven by factors including increased automation across various industries and the global shift towards energy-efficient technologies.

According to a recent report by Market Research Future, the electric actuator market is anticipated to grow at a compound annual growth rate (CAGR) of approximately

6.8% over the next decade. Innovations in smart actuators and advancements in robotics are primarily contributing to this market dynamism, as industries seek to enhance operational efficiency and reduce costs.

As businesses transition to automated systems, it’s essential to keep an eye on the latest trends in actuator technology.

Tip: Consider investing in modular actuator systems, which offer flexibility and scalability for diverse applications. Additionally, ensuring compatibility with IoT-enabled devices can significantly improve system integration and data analysis capabilities, further benefiting operational performance.

At the 138th Canton Fair 2025, cutting-edge electric actuator solutions were showcased, demonstrating how technology can meet the rising demand for efficiency in manufacturing and processing sectors.

Tip: Stay informed about key players in the market; collaborating with innovative suppliers can provide access to the latest solutions and help improve your competitive edge.

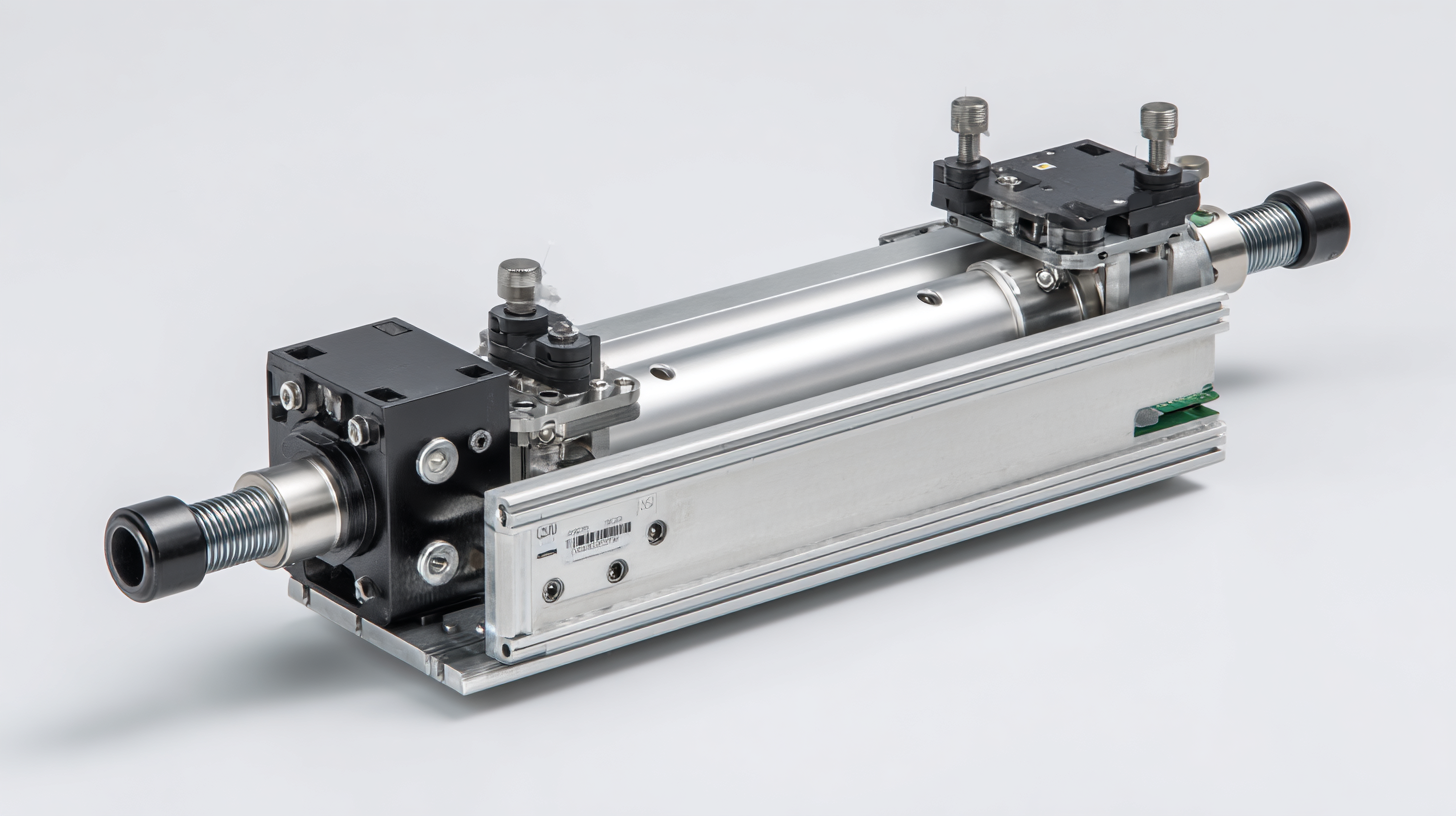

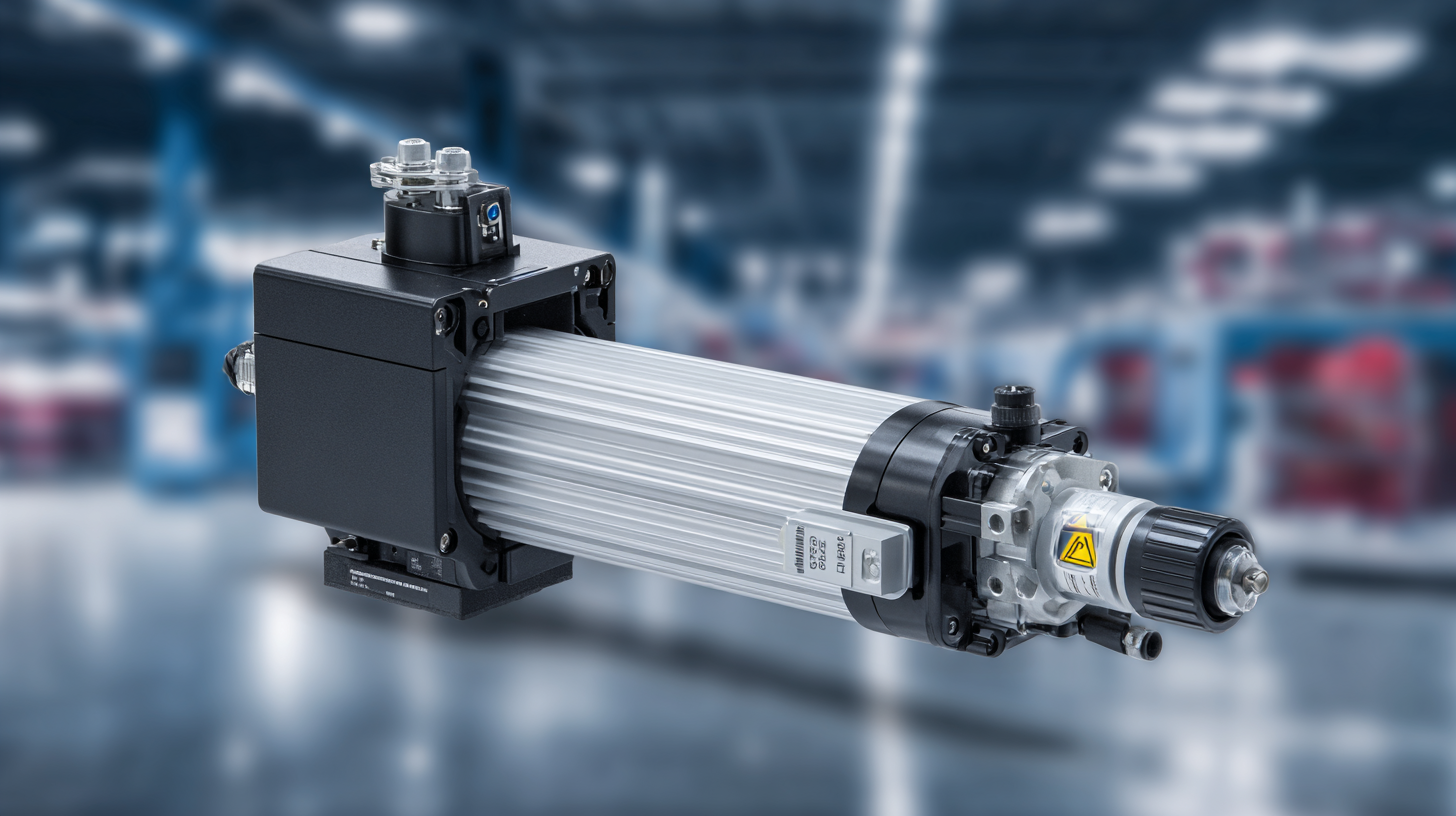

At the 138th Canton Fair 2025, innovative electric actuators were showcased, highlighting their potential to revolutionize various industries. These next-generation electric actuators are designed with a keen focus on three key features: efficiency, precision, and sustainability. By integrating advanced technologies, these actuators significantly reduce energy consumption while enhancing performance, making them essential for modern applications that require reliability and low operational costs.

The precision of these electric actuators is another standout attribute. With sophisticated control systems, they offer unparalleled accuracy in movement and positioning, catering to sectors like robotics, manufacturing, and automation. This level of precision not only improves product quality but also minimizes waste, further contributing to a sustainable operational model. As industries increasingly prioritize eco-friendly solutions, the development of these sustainable electric actuators represents a crucial step towards a greener future.

The recent unveiling of innovative electric actuator solutions at the 138th Canton Fair 2025 highlights a significant shift in automation technology. A comparative analysis reveals that electric actuators offer distinct advantages over traditional hydraulic systems, particularly in energy efficiency and operational costs. According to a report by the International Energy Agency (IEA), electric actuators can deliver up to 30% energy savings compared to hydraulic counterparts. This efficiency stems from the lack of energy loss typically associated with hydraulic fluid transfers and the ability to precisely control power usage.

Moreover, maintenance and environmental concerns further tilt the balance in favor of electric actuators. A study conducted by MarketsandMarkets predicted that the global electric actuator market will reach $36 billion by 2025, driven largely by their lower maintenance requirements and reduced risk of fluid leaks. As regulations become stricter on environmental impacts, businesses are increasingly looking for solutions that minimize their carbon footprint. With electric actuators producing less waste and being inherently cleaner, their growing adoption underscores a trend towards sustainable engineering solutions across various industries.

The growing demand for electric actuators in manufacturing and robotics has become increasingly evident, as industries seek efficient and precise control solutions. According to a report by MarketsandMarkets, the global electric actuator market is projected to reach USD 38.51 billion by 2025, growing at a CAGR of 6.2%. This trend reflects the increasing integration of automation and the need for advanced control systems in various applications, ranging from industrial machinery to automated robotic systems.

As industries phase out traditional pneumatic and hydraulic systems, electric actuators offer significant advantages such as energy efficiency, reduced maintenance requirements, and greater accuracy. A report by Grand View Research highlights that the robotics sector alone is expected to contribute significantly to this growth, with electric actuators being vital components for achieving higher performance in robotic applications. The trend aligns with a broader shift toward Industry 4.0 principles, which emphasize connectivity, data exchange, and smart manufacturing technologies, further fueling the adoption of electric actuators as core components in modern automated processes.

| Application Domain | Expected CAGR (%) | Market Size (USD Million) | Key Features |

|---|---|---|---|

| Manufacturing | 8.5% | 1,200 | Energy efficiency, precision control |

| Robotics | 10.2% | 800 | High responsiveness, compact design |

| Automotive | 7.8% | 950 | Durable design, integration with electronic systems |

| Aerospace | 6.5% | 500 | Lightweight materials, precision engineering |