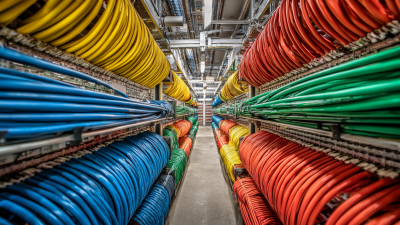

The demand for high-speed internet and reliable communication systems has propelled the fiber optic cable installation market to unprecedented heights, with the global fiber optic cable market projected to reach $8.3 billion by 2025, growing at a CAGR of 10.2% from 2020. This surge in demand necessitates meticulous planning and execution of installation projects to ensure optimal performance. A well-structured installation process not only minimizes disruptions but also enhances long-term reliability and efficiency of the network. As organizations increasingly adopt fiber optics to meet their data transmission needs, following a comprehensive checklist during fiber optic cable installation becomes essential.

This blog aims to provide essential guidelines to streamline the installation process, address common challenges, and ensure a successful project outcome in this dynamic industry.

When selecting the right fiber optic cable for your project, understanding the market landscape is crucial. The global fiber optic cable accessories market was valued at approximately USD 7.26 billion in 2022, and it is anticipated to grow significantly in the coming years, underscoring the increasing demand for reliable connectivity solutions. With such robust growth, professionals must focus on specific factors like the application environment. For instance, deploying fiber optic cables in harsh settings, such as permafrost regions, requires specialized considerations to address challenges like signal degradation. Techniques such as wavelet denoising have shown promise in effectively processing fiber optic signals in these demanding conditions.

Furthermore, as the telecommunications sector continues to evolve, optimizing deployment strategies can make a substantial difference in the speed and cost-effectiveness of fiber network rollouts. Studies indicate that implementing innovative deployment tactics can enhance returns for telecom companies, allowing for broader high-speed access. Additionally, projects like the submarine cable feasibility studies between Chile and Antarctica highlight the critical need for precise planning and execution in securing the infrastructure that underpins global communication. As fiber optic technology advances, staying informed and prepared with an essential installation checklist will be pivotal for the success of any project.

| Criteria | Description | Importance | Notes |

|---|---|---|---|

| Cable Type | Single-mode vs Multi-mode | High | Select based on distance and bandwidth needs |

| Cable Jacket | Indoor vs Outdoor | Medium | Ensure appropriate environmental ratings |

| Fiber Count | Number of fibers required | High | Plan for future expansion |

| Connector Type | LC, SC, ST, etc. | Medium | Compatibility with equipment |

| Installation Method | Aerial vs Underground | High | Consider site conditions and regulations |

Proper site assessment is crucial for the successful installation of fiber optic cables, particularly in subsea environments where infrastructure serves as a backbone for global communication. With subsea fiber-optic cables carrying over 95 percent of international data, the significance of thorough site evaluations cannot be overstated. A detailed site assessment allows engineers to identify potential risks and challenges, such as underwater topography, seismic activity, and existing infrastructures that can impact cable placement and longevity.

Recent studies highlight that inadequate site assessments can lead to significant operational disruptions and increased maintenance costs. For instance, sites prone to natural disturbances or high traffic from maritime activities can pose threats to the integrity of cable installations. Therefore, employing advanced modeling techniques, like those used in photovoltaic power plant analysis, can be beneficial for predicting shading losses from potential obstructions, ensuring optimal cable performance and reliability. By incorporating these analyses into the site assessment process, project teams can better safeguard their investment and contribute to the resilience of cyber infrastructures under geopolitical pressures.

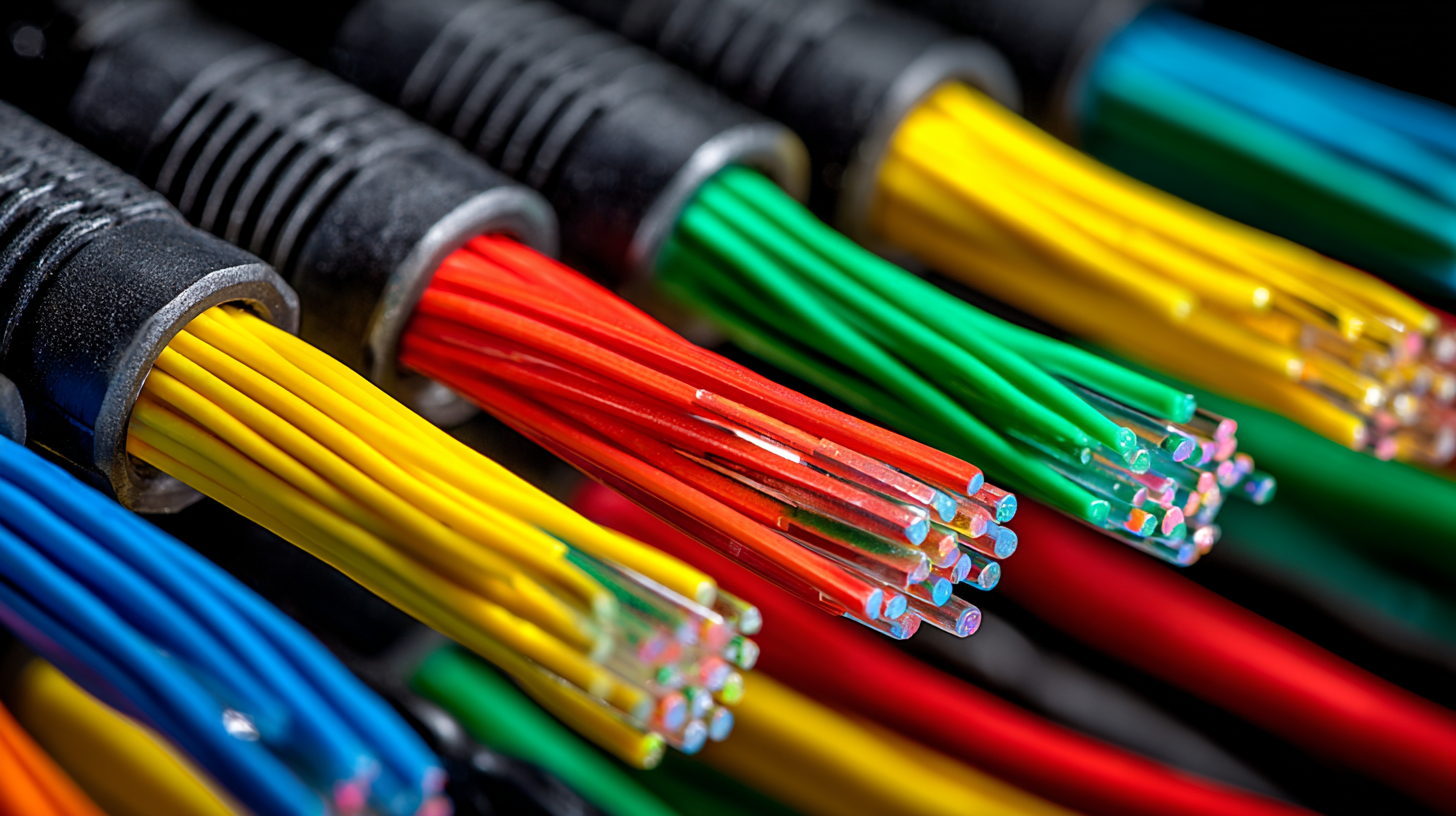

When undertaking a fiber optic cable installation project, having the right tools and equipment is crucial for ensuring a smooth and efficient process. Essential tools include a high-quality fusion splicer, which allows for precise connection of fiber strands, and a good optical power meter to test and measure transmission quality. Additionally, a fiber cleaver ensures clean cuts, minimizing signal loss during splicing. Investing in a reliable cable reel and appropriate hand tools will streamline the installation process, making your project more manageable.

Tips: Always keep your tools organized and within reach to reduce downtime during your work. Consider using a tool belt to carry essential items like your cleaver and scissors. Furthermore, familiarize yourself with the specifications of the fiber cables being installed; this knowledge can significantly enhance your efficiency and prevent potential mishaps.

Don’t overlook the importance of personal protective equipment (PPE) as well. Safety glasses, gloves, and hard hats protect you from potential hazards on the job site. Always ensure that your tools are in good condition before starting, as damaged equipment can lead to delays and safety issues. By prioritizing the right tools and protective gear, you can enhance the overall success of your fiber optic cable installation project.

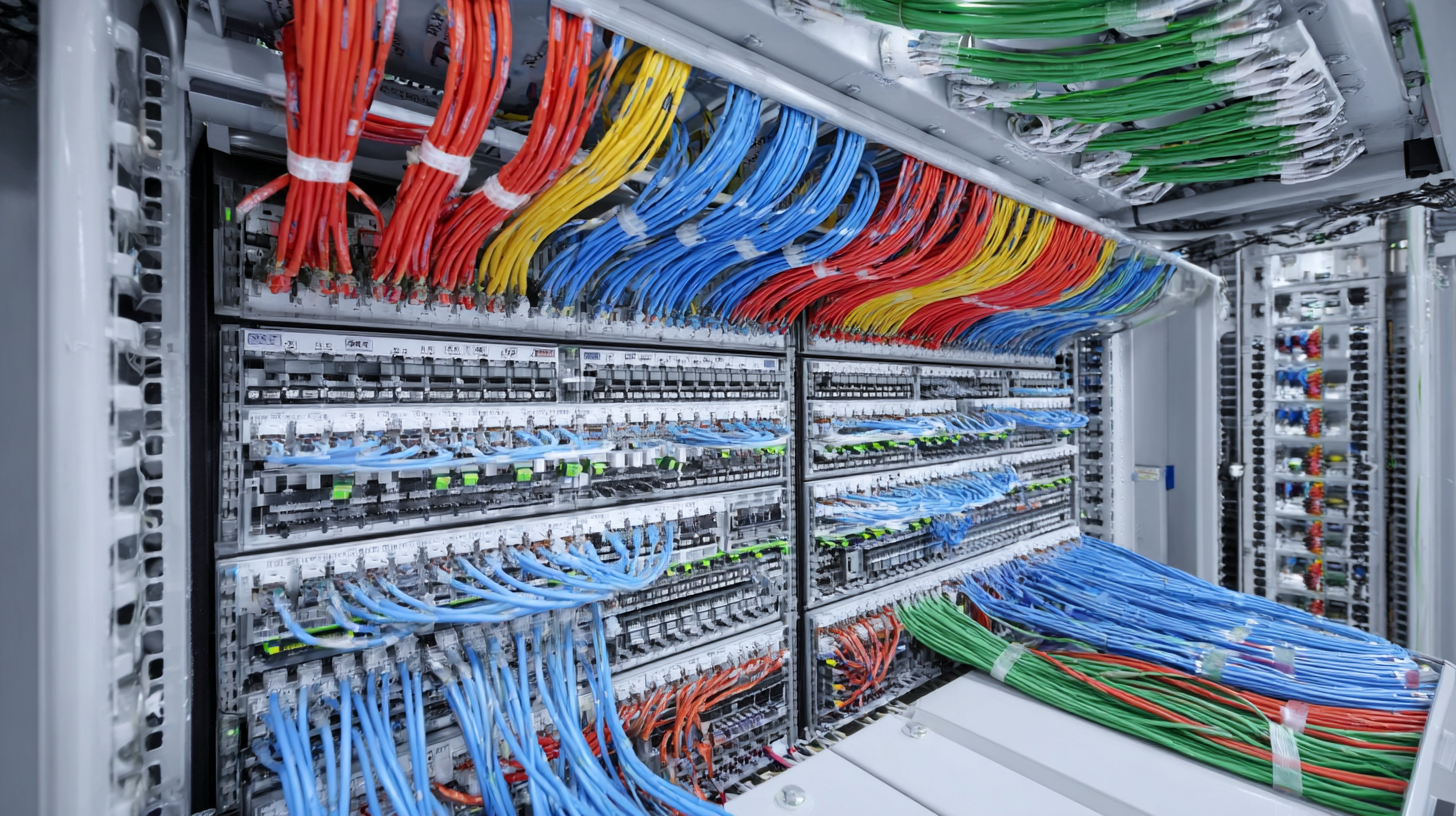

When it comes to fiber optic cable installation, adhering to industry standards and best practices is crucial to ensure a successful project. One of the primary guidelines is to carefully plan and assess the installation environment. This includes evaluating the physical layout, potential obstacles, and existing infrastructure. A thorough site survey allows installers to identify any potential challenges early on, which can significantly reduce the risk of delays and complications during the installation process.

Another essential practice is to follow proper handling and installation techniques to protect the delicate fibers within the cables. This means minimizing bends, avoiding crush risks, and maintaining appropriate tension during installation. It is important to adhere to the manufacturer's specifications for installation, as these can vary based on the cable type and intended application. Additionally, maintaining a clean working environment and employing protective measures can help prevent damage from contaminants that could affect the cable's performance over time.

Finally, ongoing training and certification for installation personnel cannot be overlooked. Keeping technicians updated on the latest technologies, installation methods, and safety protocols is vital for maintaining high standards within the industry. This not only enhances the quality of work but also fosters confidence among clients regarding the reliability of their fiber optic networks. By following these best practices, installers can ensure a successful and efficient fiber optic installation project.

When embarking on a fiber optic installation project, it's crucial to recognize the common challenges that can arise and develop strategies to overcome them. One of the primary obstacles is environmental conditions, such as extreme weather or uneven terrain. These factors can affect both the installation process and the longevity of the network. To mitigate these issues, conducting a thorough site assessment prior to installation is essential. This assessment can identify potential hazards, allowing for the implementation of protective measures and choosing materials suited for the environment.

Another significant challenge is the skill level of the installation team. Fiber optic installation requires specialized knowledge and experience to ensure proper technique and equipment use. To address this, investing in comprehensive training programs for technicians is vital. Additionally, utilizing experienced contractors can help bridge knowledge gaps. Furthermore, establishing a clear communication plan among team members can facilitate troubleshooting during the installation process, leading to a more efficient workflow and higher quality outcomes. Addressing these common challenges head-on not only enhances the installation experience but also contributes to the overall success and reliability of the fiber optic network.