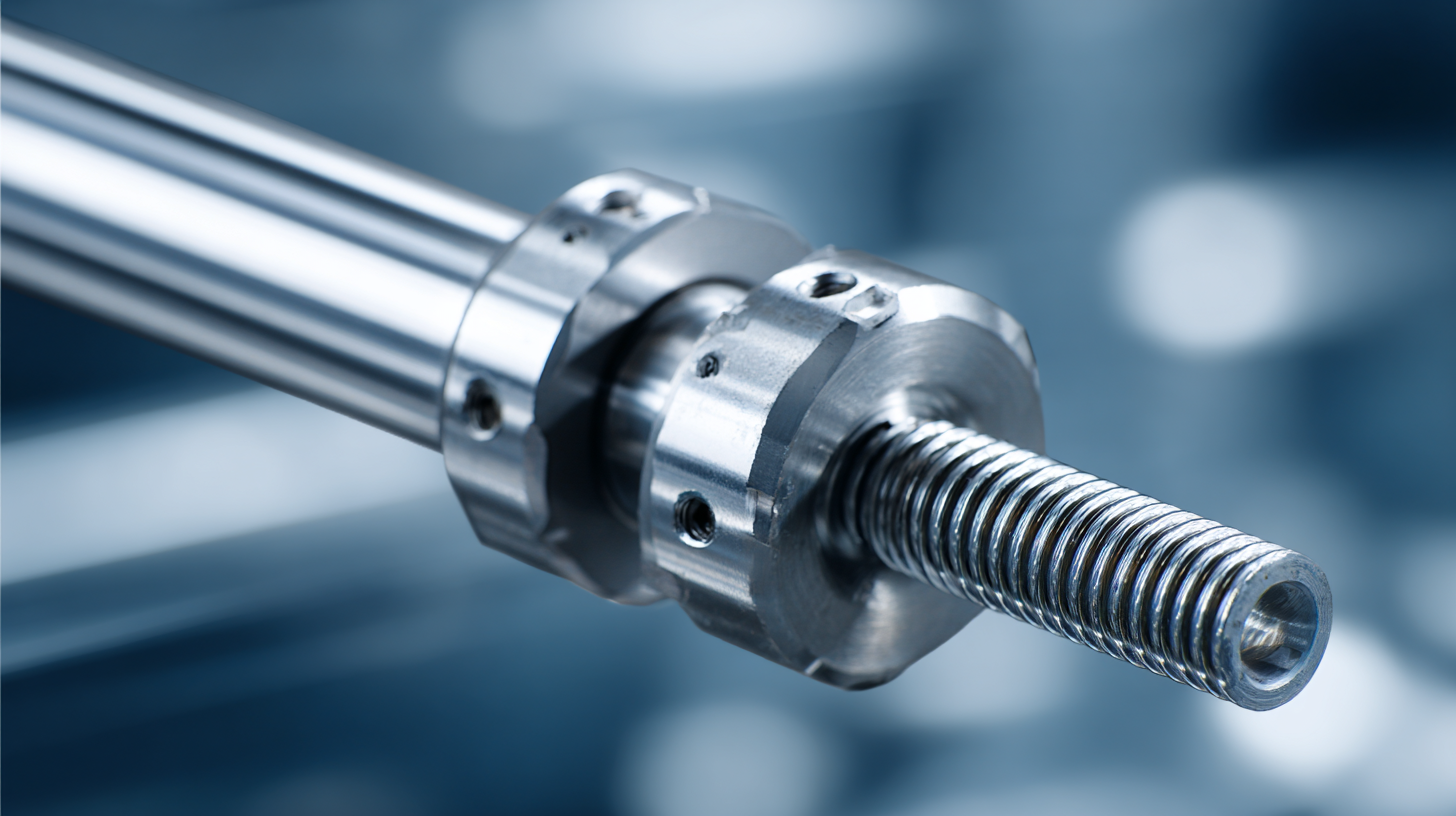

When selecting the appropriate lead screw for your application, various factors must be considered to ensure optimal performance and efficiency. According to a report by the Research and Markets, the global lead screw market is projected to reach USD 3.02 billion by 2026, growing at a CAGR of 5.2% between 2021 and 2026. This growth underlines the increasing importance of lead screws in automation, robotics, and precision machinery. Choosing the right lead screw can significantly impact the accuracy, speed, and torque of your system. Factors such as screw type, material, and thread design play crucial roles in performance characteristics. Therefore, understanding these elements is vital for engineers and designers to make informed decisions that enhance overall system functionality and longevity.

Lead screws are essential components in various mechanical applications, providing reliable motion control for industrial machines, automotive designs, and precision instruments. Understanding their basic construction and operational principles can significantly affect performance outcomes. Typically made from stainless steel or bronze, a lead screw converts rotational motion into linear movement through its threaded design. According to industry reports, the global lead screw market is expected to grow at a CAGR of about 5% from 2023 to 2030, driven by increasing automation across different sectors.

When selecting a lead screw for your application, it’s crucial to consider factors such as load capacity, speed requirements, and accuracy. For example, Acme screws offer high-load capacities, while ball screws provide enhanced efficiency and precision for high-speed applications. Depending on your needs, ensure you calculate the required torque and consider environmental factors that may impact screw performance, such as temperature fluctuations and exposure to contaminants.

**Tips:** Always consult with manufacturers about the specific technical requirements for your lead screw application. Utilize simulation software to predict performance within your system. Remember, choosing the right lead screw can reduce wear and extend the lifespan of your machinery, ultimately leading to cost savings over time.

When selecting the right lead screw for your application, it's essential to identify key specifications that will ensure optimal performance. Parameters such as lead pitch, material, and load capacity play a crucial role in the effectiveness of the lead screw. According to a report by the Machinery Manufacturers Association, the lead screw's lead pitch directly affects its speed and resolution; a finer lead allows for greater positional accuracy but can reduce speed, while a coarser lead offers quicker motion at the expense of control.

When selecting the right lead screw for your application, it's essential to identify key specifications that will ensure optimal performance. Parameters such as lead pitch, material, and load capacity play a crucial role in the effectiveness of the lead screw. According to a report by the Machinery Manufacturers Association, the lead screw's lead pitch directly affects its speed and resolution; a finer lead allows for greater positional accuracy but can reduce speed, while a coarser lead offers quicker motion at the expense of control.

Tips: Always consider the load that the lead screw will bear. The maximum load capacity must align with your application's requirements to avoid premature wear or failure. Utilizing the right materials, such as stainless steel for corrosion resistance or bronze for improved wear properties, can significantly enhance the lifespan of your lead screw.

Another important factor is the type of nut used with the lead screw. Plastic nuts offer quieter operation and lower friction but may wear out faster under heavy loads. Conversely, metal nuts can handle higher loads but may generate more friction. According to industry standards, approximately 70% of lead screw failures are due to incompatibility between the lead screw and the nut material or design. Thus, carefully matching these components can lead to more efficient and reliable operation.

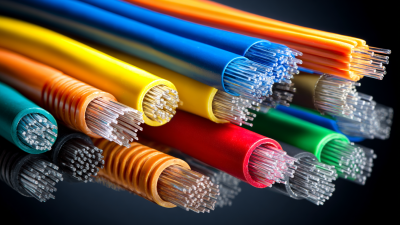

When selecting a lead screw for any application, the material choice plays a critical role in ensuring both optimal performance and durability. Common materials used for lead screws include steel, aluminum, and polymers, each offering unique benefits. Steel lead screws are known for their high strength and wear resistance, making them ideal for heavy-duty applications where high load capacities are required. On the other hand, aluminum lead screws are lightweight and provide excellent corrosion resistance, suitable for applications where weight reduction is crucial.

Additionally, polymer lead screws can be advantageous in environments where noise reduction and low friction are necessary. These screws often require less lubrication and can operate silently, making them perfect for applications in medical equipment or precision instruments. Evaluating the environmental factors, such as temperature and exposure to chemicals, will also influence the material choice. By thoroughly assessing the application parameters and the properties of potential materials, one can select the most appropriate lead screw to ensure longevity and efficiency in the intended setup.

This bar chart compares the load capacity of different lead screw materials. It showcases the performance of each material type, helping you make an informed decision based on your application requirements.

When selecting the right lead screw for a specific application, it's essential to thoroughly analyze load requirements and motion dynamics. Understanding the forces acting on the lead screw, including axial loads and torque, is critical to ensure it can handle the demands of the project. For instance, in scenarios involving high-speed train operations over bridges, the interaction between the dynamic loads generated by the trains and the structural responses of the bridge highlights the need for precise calculations. A lead screw must be robust enough to withstand these variations in load and maintain smooth motion, which is pivotal for the safety and stability of the entire system.

Additionally, the motion dynamics of lead screws are significantly influenced by their design and the intended use. In advanced applications, such as helicopter attitude simulation, the mechanism's ability to reproduce complex motions like yaw, roll, and pitch is crucial. This level of precision in motion is driven by the correct selection of lead screw specifications, including pitch and material, to ensure that the device operates accurately under varying dynamic conditions. Thus, a comprehensive understanding of both load characteristics and motion requirements is vital to making an informed decision about which lead screw to choose for optimal performance in any application.

| Application Type | Load Requirement (lbs) | Lead Screw Diameter (inches) | Material | Max Speed (inches/min) | Length (inches) |

|---|---|---|---|---|---|

| 3D Printer | 20 | 0.25 | Brass | 300 | 12 |

| CNC Machine | 150 | 0.5 | Steel | 600 | 24 |

| Automated Stage | 80 | 0.375 | Aluminum | 400 | 18 |

| Medical Device | 30 | 0.25 | Plastic | 100 | 10 |

When selecting the right lead screw for your application, it's crucial to consider environmental factors and installation conditions that can significantly influence performance. The choice of materials, for instance, is essential in environments that experience extreme temperatures, humidity, or corrosive elements. A lead screw made of stainless steel would be preferred in a damp or corrosive environment to ensure longevity and reliability. Additionally, the presence of dust or debris could affect the operating efficiency, necessitating a design that includes protective covers or seals.

Installation conditions must also be assessed to maximize the efficiency of the lead screw. It is important to evaluate the available space, alignment, and mounting options to ensure that the lead screw can operate smoothly without excessive wear or stress. Factors such as load requirements and motion profiles should be determined early in the selection process to ensure compatibility. Proper attention to these environmental and installation conditions will lead to a more effective and durable solution, ultimately enhancing the overall functionality of your system.