In the dynamic landscape of modern manufacturing, the search for efficiency and precision has led to the evolution of numerous automation technologies, among which the gantry system stands out as a pivotal solution. This blog explores the diverse industry applications of gantry systems, delving into their significance and versatility across various sectors, from automotive to electronics and beyond. As we investigate what constitutes the best gantry system for contemporary manufacturing needs, we will scrutinize key features, benefits, and real-world case studies that illuminate the transformative impact of these systems.

Whether you are a seasoned industry professional looking to optimize your processes or a newcomer eager to understand the technological advancements shaping manufacturing, this exploration will provide valuable insights into the critical role gantry systems play in fostering innovation and productivity in today's competitive market.

When it comes to modern manufacturing, choosing the right gantry system is critical for optimizing productivity and efficiency. Core features such as load capacity, precision, and automation capabilities distinguish various gantry systems tailored to specific industry applications. According to a recent report by the International Federation of Robotics, the market for automation technologies, including gantry systems, is projected to grow by 10% annually through 2025. This growth emphasizes the need for manufacturers to understand the strengths of different systems to remain competitive.

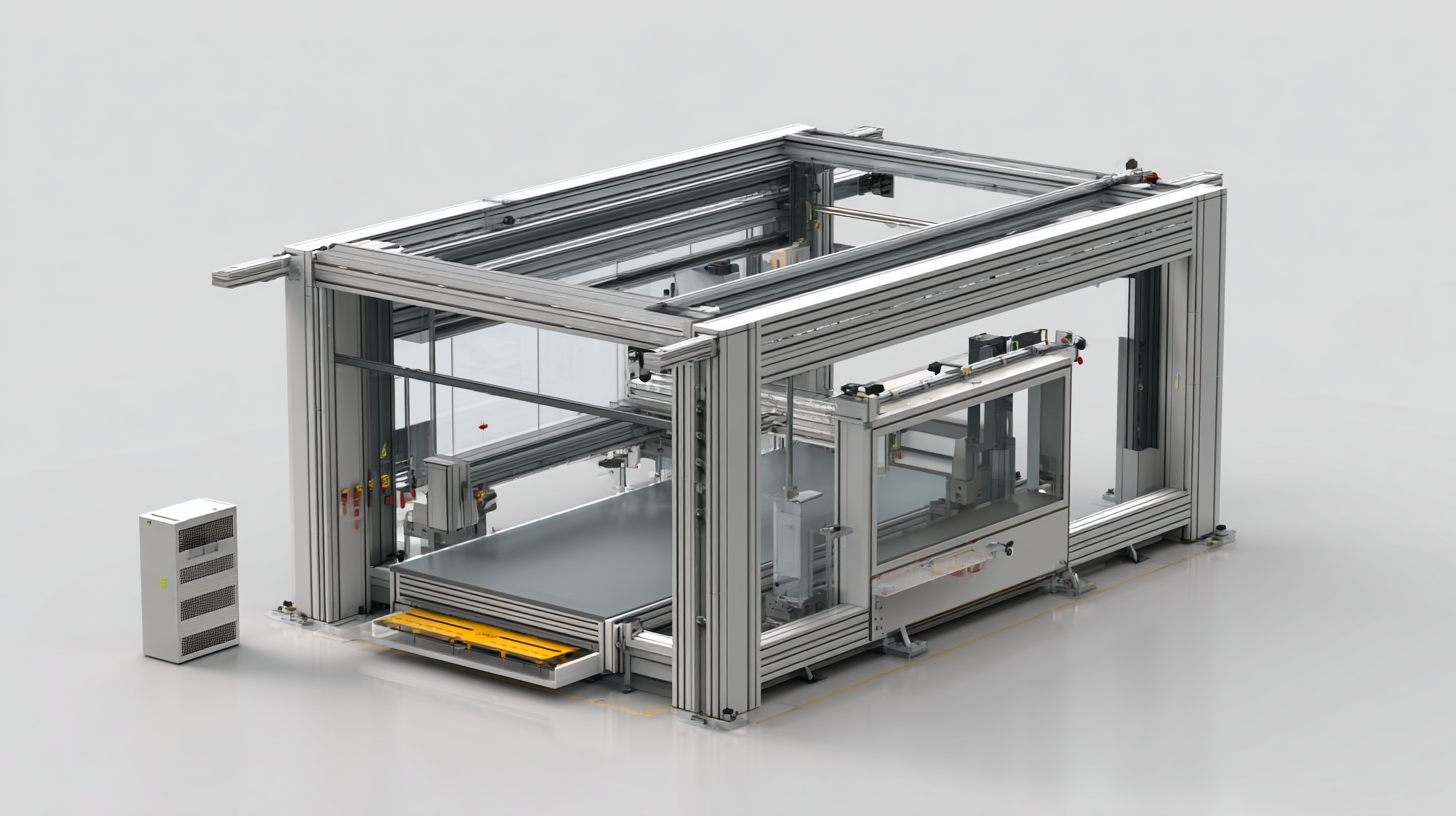

Load capacity is a fundamental feature that defines a gantry system's application. Systems designed for heavy-duty tasks, like those found in the automotive industry, often boast capacities exceeding 5 tons. Meanwhile, lighter models, which are preferable in electronics manufacturing, can efficiently handle loads around 500 kg. Additionally, precision plays a pivotal role; for instance, a recent industry survey revealed that 88% of manufacturers consider precision to be the most important factor when selecting automation equipment. Integration capabilities with existing systems further enhance versatility, allowing manufacturers to leverage advancements in robotics and IoT technology seamlessly.

Ultimately, the choice of a gantry system must align with the specific needs of a manufacturing operation, balancing factors like size, capacity, and level of automation. A comprehensive understanding of these core features empowers businesses to make informed decisions that can significantly impact their operational efficiency and bottom line.

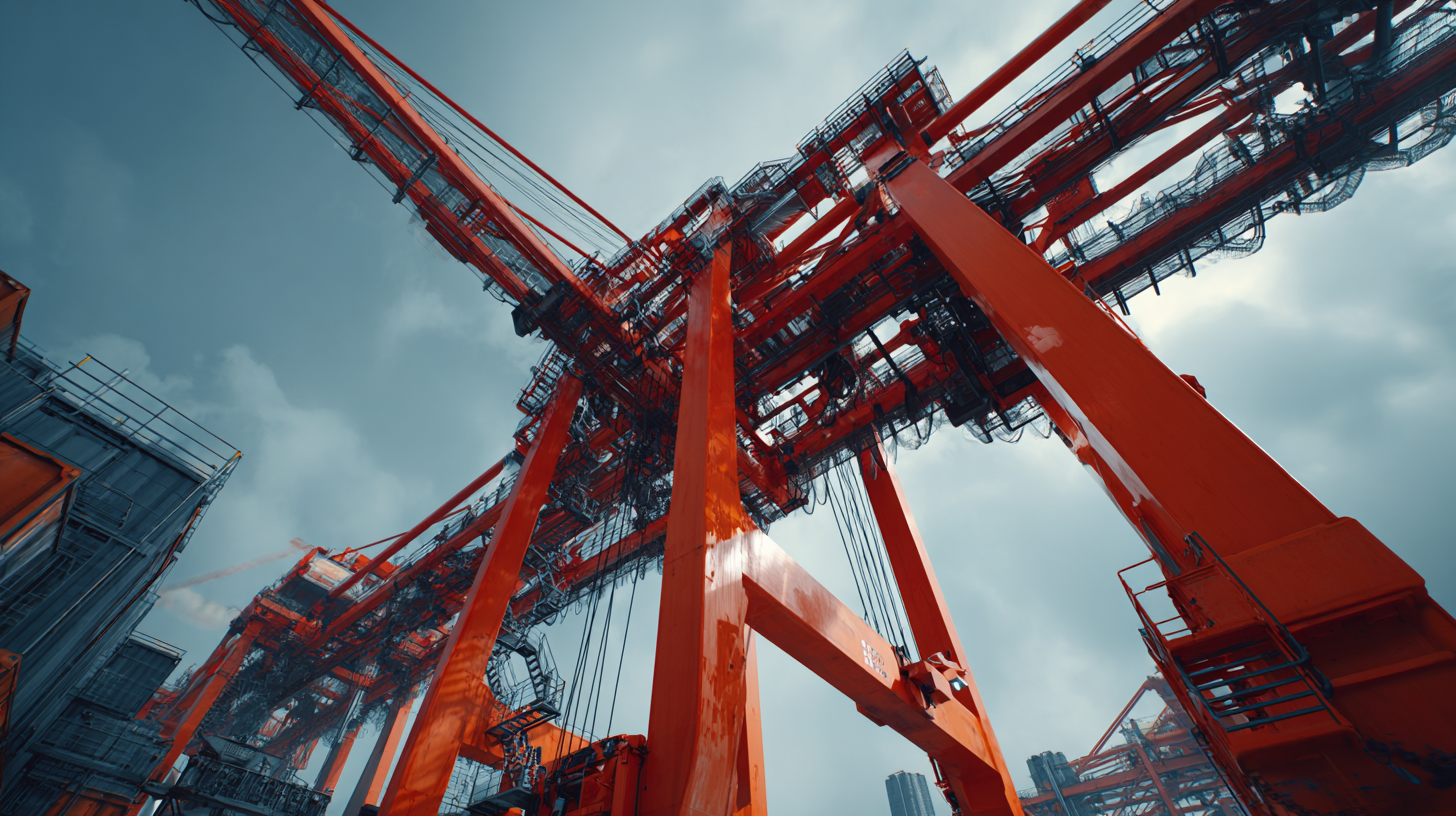

When it comes to selecting the ideal gantry system for contemporary manufacturing, the choice between fixed and mobile gantry configurations can significantly impact productivity and flexibility. Fixed gantry systems, known for their robustness and stability, are usually best suited for environments where heavy loads are consistently handled, such as in automotive manufacturing or metal fabrication. These systems often offer precision and repeatability, ensuring that operations can be carried out seamlessly. However, their immobility can be a drawback in dynamic settings where the production line may require frequent reconfiguration or adjustments.

On the other hand, mobile gantry systems provide exceptional versatility, allowing manufacturers to move the lifting equipment as needed. This mobility makes them ideal for operations that demand adaptability, such as assembly lines or construction sites where flexibility is key. Additionally, mobile gantries often require less space and can be reconfigured quickly, minimizing downtime during production transitions. However, the trade-off might include lower load capacities and potential stability issues compared to fixed systems. Balancing these performance metrics against the specific demands of your manufacturing processes is crucial for optimizing efficiency and effectiveness in modern production environments.

This chart illustrates the performance metrics of fixed and mobile gantry systems across various manufacturing needs. The data reflects parameters such as load capacity, mobility, flexibility in design, and cost-efficiency.

When it comes to modern manufacturing, selecting the right gantry system is crucial for optimizing workflow and efficiency. Different industries have unique demands that necessitate tailored solutions. For instance, automotive manufacturing often requires heavy-duty gantry systems capable of handling large parts and maintaining precision during assembly. Systems designed specifically for this sector are typically robust, featuring advanced control technologies to ensure high levels of automation and accuracy.

In contrast, the aerospace industry demands gantry systems that offer exceptional precision and flexibility. These systems must accommodate complex shapes and materials while adhering to stringent quality standards. Therefore, lightweight but rigid constructions, coupled with advanced motion control, are essential to meet the rigorous specifications of aerospace production. Additionally, industries such as electronics manufacturing may prioritize compact gantry systems that can operate in confined spaces while providing the versatility needed for various assembly tasks. By understanding these specific requirements, manufacturers can make informed decisions that greatly enhance operational efficiencies and production capabilities.

When considering the best gantry system for modern manufacturing needs, a thorough comparative cost analysis is crucial. Gantry systems, known for their versatility and efficiency in material handling, often present a higher initial investment compared to alternative solutions such as forklifts or conveyor belts. However, the long-term savings from reduced labor costs, increased safety, and improved operational efficiency must also be taken into account.

Investing in a gantry system can lead to significant cost benefits over time. These systems typically require less maintenance and provide greater precision in handling heavy loads, minimizing the risk of damage to both the materials and the facility. Additionally, with the automation of tasks, organizations can shift their workforce focus toward more value-added activities. By contrasting the upfront costs and operational efficiencies, manufacturers can better understand the true return on investment that a gantry system offers when juxtaposed with conventional handling solutions. This analysis guides businesses in making informed decisions tailored to their unique operational demands.

As manufacturing evolves towards greater automation, gantry systems are experiencing significant advances to meet the industry's needs. Traditional gantry systems, known for their robustness and versatility, are being reimagined to incorporate smart technologies that enhance their efficiency and adaptability. With the integration of IoT devices, these systems can now offer real-time data analytics, predictive maintenance, and improved operational visibility. This shift not only optimizes production processes but also reduces downtime, a critical factor in modern manufacturing environments.

The future of gantry systems also lies in their ability to collaborate seamlessly with other automated equipment. As factories trend toward more interconnected networks, gantry systems equipped with advanced robotics and AI capabilities are crucial for streamlined workflows. These systems can adapt to various tasks, ranging from precision assembly to heavy material handling, showcasing their multifaceted applications. Moreover, the advancement of lightweight materials and precise motion control technologies is paving the way for more agile and efficient gantry designs, essential for maintaining competitiveness in an increasingly automated landscape.

| Gantry System Type | Load Capacity (kg) | Speed (m/s) | Travel Range (m) | Automation Compatibility | Typical Applications |

|---|---|---|---|---|---|

| Single Girder Gantry | 500 | 1.5 | 10 | Yes | Lightweight Material Handling |

| Double Girder Gantry | 1000 | 2.0 | 15 | Yes | Heavy Material Handling |

| Portable Gantry | 300 | 1.0 | 5 | No | Maintenance and Repair |

| Articulated Gantry | 700 | 1.8 | 12 | Yes | Complex Assembly Operations |

| Heavy-Duty Gantry | 1500 | 1.2 | 20 | Yes | Manufacturing and Fabrication |