In the ever-evolving landscape of manufacturing, the significance of plastic injection molds cannot be overstated. These molds are not just tools; they are the backbone of the production process, offering unparalleled precision, efficiency, and versatility. According to Dr. Emily Tran, a renowned expert in the field of plastic engineering, "Plastic injection molds have revolutionized manufacturing by enabling complex designs with minimal waste." This rings especially true as industries seek to balance productivity with sustainability, making the adoption of advanced mold technologies a priority.

With plastic injection molds, manufacturers can create intricate components that meet stringent specifications, significantly reducing assembly time and costs. The ability to produce large quantities of uniform products in a single run while maintaining high-quality standards is a critical advantage in today’s competitive market. As we delve into the top benefits of plastic injection molds for your manufacturing needs, we will explore how these innovations are not only shaping the future of industrial production but also enhancing operational efficiency across various sectors.

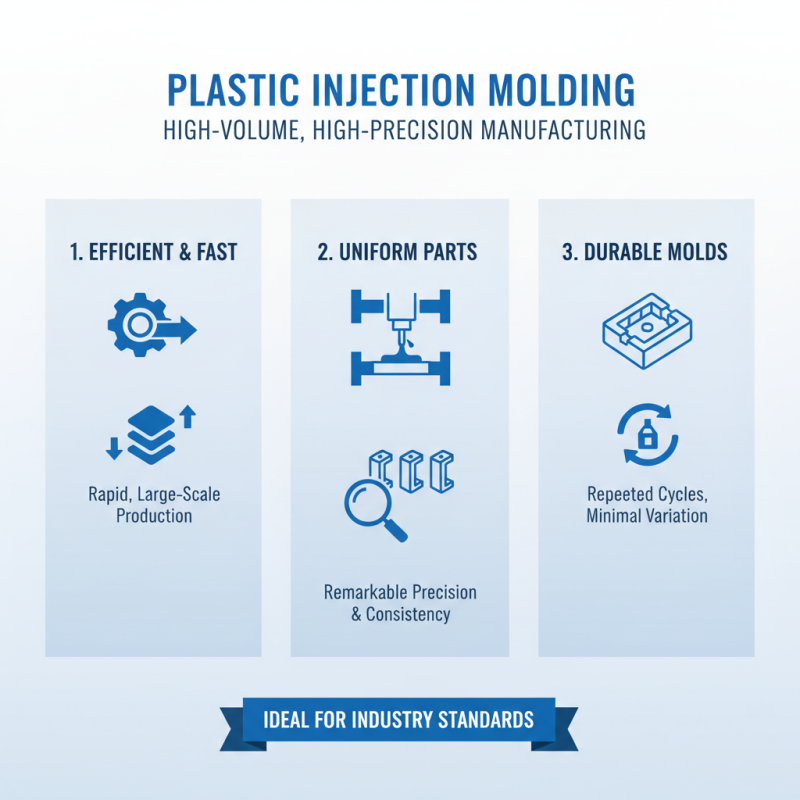

Plastic injection molding is a highly efficient manufacturing process particularly suited for high-volume production. One of the primary advantages of this method is its ability to produce large quantities of uniform parts with remarkable precision. The use of durable molds allows for repeated cycles of production, minimizing variations between each item. This consistency is crucial for industries that require large numbers of identical components, ensuring that each product meets stringent quality standards.

Moreover, the versatility of materials used in plastic injection molding opens up possibilities for innovation. Manufacturers can select from a wide array of plastics, enabling the creation of products that not only fit specific performance criteria but also allow for a variety of finishes and aesthetics. Fast cycle times further enhance productivity, making it possible to scale production quickly to meet increasing demand. This combination of efficiency, consistency, and material diversity makes plastic injection molding a compelling choice for manufacturers looking to optimize their production processes while maintaining high quality and cost-effectiveness.

The manufacturing landscape has evolved significantly, with plastic injection molding emerging as a leading method due to its cost efficiency. According to a report by the Plastics Industry Association, injection molding can reduce the cost of production by as much as 50% compared to traditional methods like CNC machining or 3D printing. This significant reduction in manufacturing costs is largely attributed to the high production speed and the ability to create complex geometries without increased labor costs. In high-volume production scenarios, the return on investment (ROI) for injection molds can be realized quickly, making it a preferred choice for manufacturers seeking to optimize their budgets.

Another critical advantage of plastic injection molds is their capability for material efficiency. Data from the American Society for Testing and Materials (ASTM) indicates that injection molding can minimize waste material by up to 90%, especially when using advanced thermoplastics. This is particularly important in an era where sustainability and environmental responsibility are at the forefront of manufacturing practices. By reducing waste and maximizing material usage, manufacturers not only cut costs but also enhance their overall sustainability profile, aligning with industry standards and consumer expectations. This dual focus on cost efficiency and environmental stewardship makes plastic injection molding a compelling option for modern manufacturing needs.

Plastic injection molding is a transformative technique that significantly enhances product design flexibility. Unlike traditional manufacturing methods, plastic injection molds allow for intricate designs and shapes to be produced with high precision, which can be a game-changer for designers. This flexibility enables the creation of complex geometries that would be challenging or even impossible to achieve with other manufacturing processes. Designers can experiment with innovative concepts without worrying about drastic increases in costs or production timelines.

Tips for maximizing design flexibility include using 3D modeling software during the design phase. This allows for virtual testing and adjustment of designs before committing to physical prototypes. Additionally, consider modular designs that can be easily modified or adapted for different applications. By doing so, manufacturers can create versatile products that can be tailored to meet diverse customer needs without significant redesign efforts.

Moreover, the rapid production speeds associated with plastic injection molding facilitate quicker iterations. This allows design teams to refine their concepts faster, integrating feedback and making necessary adjustments in real time. Embracing this iterative approach not only streamlines the design process but also enhances the final product's quality, making it more aligned with market demands and consumer preferences.

This chart illustrates the top benefits of using plastic injection molds in manufacturing. Each benefit is rated on a scale from 1 to 10, reflecting its importance in product design flexibility and overall production efficiency.

Plastic injection molding is increasingly recognized for its sustainability and recycling potential, positioning it as a leading choice in modern manufacturing. The process itself generates minimal waste, as excess material can often be reclaimed and reused. Moreover, many manufacturers are embracing bioplastics—sustainable materials derived from renewable sources—that fit seamlessly into the injection molding process. This transition not only reduces dependence on fossil fuels but also lowers overall carbon emissions associated with production.

For manufacturers looking to adopt sustainable practices, consider the following tips: First, evaluate the materials you are currently using and explore eco-friendly alternatives. Investing in training for your team on recycling practices will also enhance your production line’s efficiency and sustainability. Lastly, engage with suppliers who prioritize sustainable materials and practices to ensure your entire supply chain reflects your commitment to the environment.

By focusing on recycling benefits, plastic injection molding can contribute to a circular economy, where products are designed to be reused and recycled continuously. This benefits not just the environment but also enhances the brand image of businesses committed to sustainability. Adopting responsible manufacturing processes can lead to reduced costs and increased customer loyalty in an increasingly eco-conscious market.

| Benefit | Description | Impact on Sustainability | Recycling Potential |

|---|---|---|---|

| Efficiency | High production rates and reduced waste during manufacturing. | Lower energy consumption and raw material usage. | Easily recyclable materials used to create molds. |

| Precision | High accuracy in mold creation allows for better fitting parts. | Reduces the need for excess machining and adjustments. | Materials can often be reused after production. |

| Customization | Molds can be tailored to create specific designs that fulfill unique needs. | Facilitates innovative designs that can utilize recycled materials. | Supports a circular economy by allowing design flexibility. |

| Cost-Effectiveness | Lower costs for high volumes due to production efficiency. | Reduces the cost of disposal and raw materials. | Recycling lowers overall material costs over time. |

| Durability | Long-lasting molds that withstand high production runs. | Less frequent need for replacement means less waste. | Old molds can be recycled and materials repurposed. |

Plastic injection molding has become a cornerstone of modern manufacturing due to its ability to deliver high-quality parts with remarkable precision. One of the most significant advantages of this process is the exceptional level of quality control it offers. By utilizing sophisticated machinery and techniques, manufacturers can achieve tight tolerances that ensure each injection-molded component meets the required specifications. This precision is crucial in industries where even the slightest defect can lead to substantial losses, making the quality assurance process indispensable.

Tips for optimizing your quality control during injection molding include conducting regular maintenance checks on your equipment to ensure consistent performance. Additionally, implementing a robust testing protocol for mold cycles can help identify potential issues early in the production process, reducing waste and increasing efficiency. Utilizing computer-aided design (CAD) can also aid in simulating and modifying designs before production, allowing for precise adjustments that enhance overall quality.

Another key aspect of quality control in injection molding is the use of advanced materials that can withstand various manufacturing conditions while maintaining their integrity. Understanding the properties of different plastics and their behavior during molding can lead to better product outcomes. Experts emphasize training your team on the nuances of material selection and mold design, as their expertise will directly impact the quality of the final product.