In today's rapidly evolving industrial landscape, the efficiency and safety of operations are paramount. One innovative solution that has gained traction in various sectors is the cable track system. These systems not only enhance the organization of cables and hoses but also significantly reduce wear and tear on equipment, leading to longer service lives and lower maintenance costs. As industries increasingly turn to automated processes and complex machinery, the need for reliable cable management becomes even more critical.

This guide will explore the numerous advantages of cable track systems, highlighting their role in improving operational workflows, minimizing downtime, and ensuring a safer work environment. Understanding these benefits will empower businesses to make informed decisions about implementing cable track solutions tailored to their specific industrial needs.

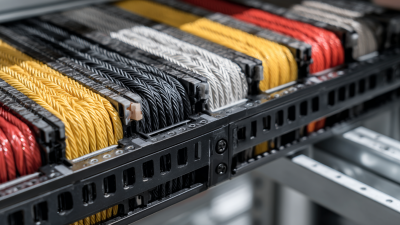

Cable track systems are rapidly gaining popularity in industrial settings, revolutionizing the way manufacturers handle power and data transmission. One of the primary benefits of these systems is their ability to enhance efficiency by reducing clutter and minimizing the risk of damage to cables. By keeping cables organized and protected within designated tracks, operators can navigate their workspaces more freely and safely, leading to better productivity.

Moreover, cable track systems offer significant flexibility and adaptability. As production needs change, these systems can be reconfigured with relative ease, accommodating different machinery and layouts without extensive downtime. This adaptability ensures that industries can swiftly respond to evolving operational demands, maintaining workflow continuity and optimizing resource allocation. The streamlined design of cable tracks not only saves space but also contributes to a cleaner working environment, ultimately supporting overall operational safety and effectiveness.

Modern cable track systems are essential in optimizing performance across various industrial applications. These systems are designed to manage and protect cable assemblies efficiently, significantly reducing wear and tear while enhancing operational reliability. One of the key features of contemporary cable track systems is their versatility in accommodating various cable types and configurations. This versatility allows industries to customize setups to meet specific machinery requirements, ensuring seamless integration and functionality.

Modern cable track systems are essential in optimizing performance across various industrial applications. These systems are designed to manage and protect cable assemblies efficiently, significantly reducing wear and tear while enhancing operational reliability. One of the key features of contemporary cable track systems is their versatility in accommodating various cable types and configurations. This versatility allows industries to customize setups to meet specific machinery requirements, ensuring seamless integration and functionality.

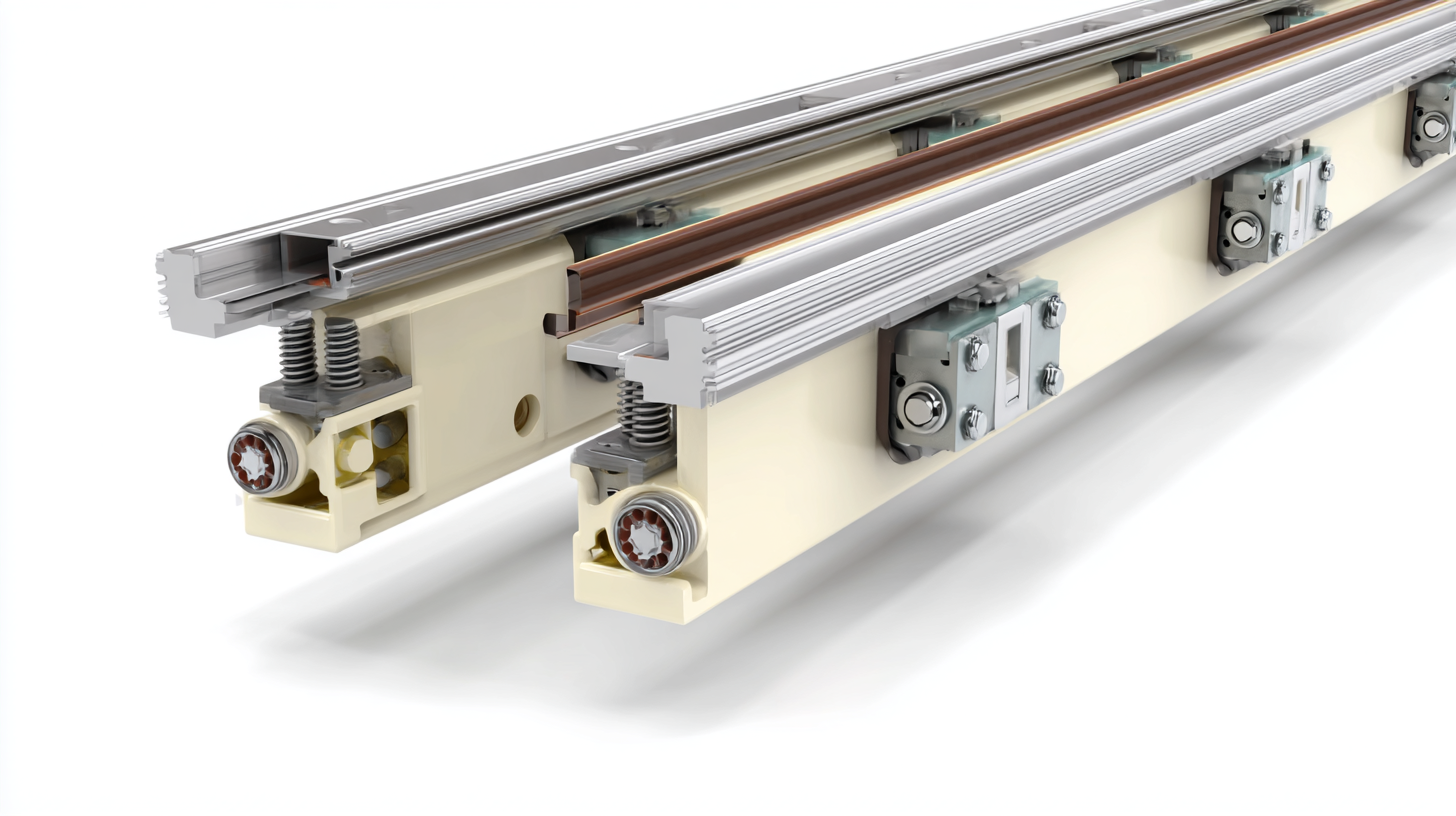

Another critical feature is the advanced materials used in constructing these cable tracks. Many modern systems utilize high-grade plastics or metals that offer enhanced durability and resistance to harsh environments, including extreme temperatures and chemicals. Additionally, the smooth operation of the cable tracks minimizes friction, leading to lower maintenance costs and improved longevity. These innovations not only streamline workflows but also contribute to safer working conditions by reducing the risk of cable damage and associated hazards. Overall, the key features of modern cable track systems play a pivotal role in boosting efficiency and effectiveness in modern industrial settings.

In the evolving landscape of modern industry, cable management has taken on a critical role in ensuring operational efficiency and safety. A comparative analysis of cable track systems versus traditional cable management solutions highlights several advantages of the former. According to a report by MarketsandMarkets, the global cable management market is projected to grow from $23.2 billion in 2021 to $33.2 billion by 2026, reflecting an increasing reliance on advanced solutions such as cable track systems. These systems offer enhanced organization and protection for cables, reducing the risk of damage that is often associated with tangled or improperly managed wiring.

Moreover, cable track systems provide superior flexibility and adaptability compared to traditional methods. Research from Allied Market Research indicates that flexible cable management solutions can reduce installation time by up to 30%. This efficiency translates to lower labor costs and minimized downtime, which is crucial in a fast-paced industrial environment. Additionally, these systems streamline maintenance processes, allowing for quicker access to cables for repairs or replacements. With the growing emphasis on safety and productivity, industries are increasingly recognizing the long-term benefits of adopting cable track systems over conventional management practices.

When installing cable track systems in a modern industrial setup, it’s essential to follow certain tips to maximize their benefits. First, ensure that the cable tracks are appropriately sized for the specific application. Selecting the right dimensions will help in accommodating various cable types and sizes while preventing tangling or wear. Additionally, consider the track's positioning—placing it in areas with minimal interference will enhance efficiency and ease of movement for machinery.

Another crucial installation tip is to pay attention to the routing of the cables. Properly routing the cables through the track can help in maintaining organization and access during maintenance. Implementing a systematic way to load and unload cables will also extend the lifespan of the system. Lastly, regular inspections after installation can catch potential issues early, ensuring that the cable track system continues to operate smoothly and effectively, providing seamless connectivity and productivity in industrial environments.

The future of cable track technology is poised for significant advancements that cater to the evolving needs of modern industries. As automation and mechanization become more prevalent, the demand for efficient cable management solutions is critical. Innovations such as lightweight materials and modular designs are transforming traditional cable track systems, allowing for greater flexibility in installation and maintenance. Companies are now leveraging advanced engineering techniques to create tracks that reduce friction and wear, ultimately extending the lifespan of cables and minimizing operational downtime.

Moreover, the integration of smart technologies into cable track systems is becoming a key trend. The use of sensors and IoT devices can enable real-time monitoring of cable status, allowing for predictive maintenance and reducing the risk of unexpected failures. This technological advancement not only enhances safety and reliability but also optimizes performance, making cable management systems more intelligent and responsive to the operational environment. As industries look to enhance productivity and reduce costs, the evolution of cable track technology will play an essential role in driving efficiency and innovation in industrial applications.

| Dimension | Details |

|---|---|

| Flexibility | Cable track systems can easily adapt to various machine layouts and configurations. |

| Durability | Made from high-quality materials that withstand harsh industrial environments. |

| Safety | Minimizes the risk of cable damage and enhances the safety of machine operation. |

| Maintenance | Requires less maintenance compared to traditional cable management solutions. |

| Future Trends | Integration of smart technologies such as IoT for real-time cable monitoring. |

| Cost Efficiency | Potential reduction in operational costs due to improved reliability and reduced downtime. |